In mechanical systems, noise and friction are two common challenges that can hinder performance, reduce efficiency, and lead to premature wear and tear. Polyamide (PA) pulleys, made from high-performance polyamide materials, offer a reliable solution to these issues. By incorporating PA pulleys into your machinery, you can achieve smoother operation, lower energy consumption, and extended service life.

The Role of PA Material in Noise Reduction

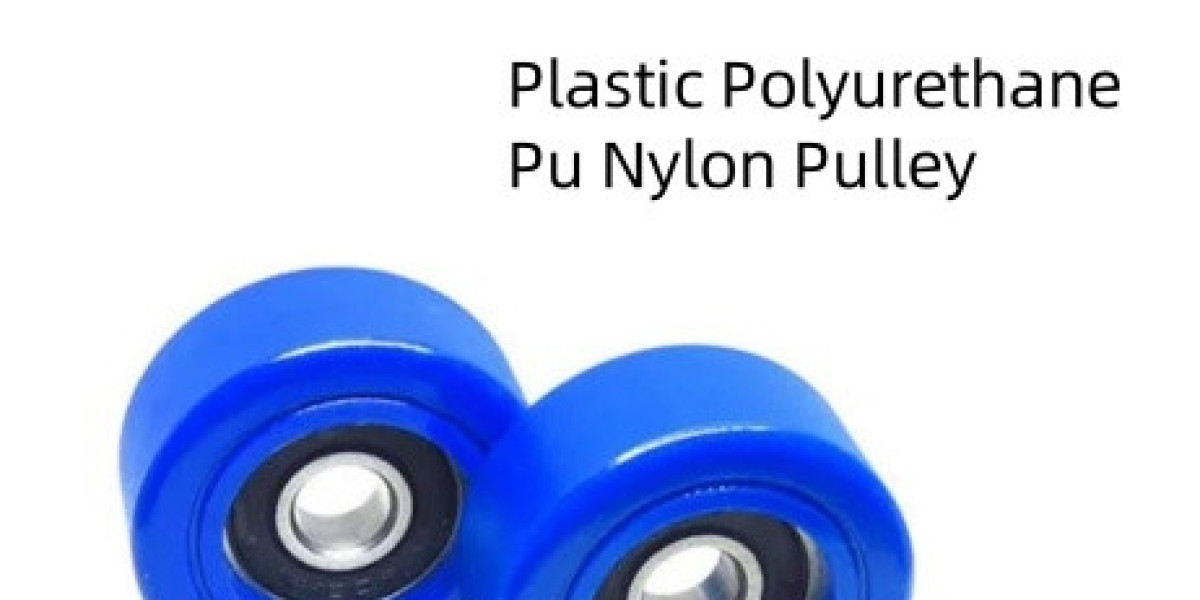

Polyamide, also known as nylon, is a versatile synthetic polymer known for its excellent mechanical properties, including high strength, durability, and resistance to wear. One of the standout features of PA is its ability to reduce noise in mechanical systems. The following aspects contribute to this noise reduction:

Absorbing Vibrations:

PA pulleys are capable of absorbing vibrations that would typically cause noise in mechanical systems. The material's inherent dampening properties help to minimize high-frequency sound waves generated by pulleys and belts. This is especially beneficial in applications that require smooth, quiet operation, such as in automotive engines, industrial machines, and conveyor systems.

Minimizing Metal-to-Metal Contact:

Unlike traditional metal pulleys, PA pulleys help reduce the amount of metal-to-metal contact between the pulley and the belt. This significantly lowers friction and prevents the screeching or clanking sounds that often result from metal parts rubbing against each other. The smooth, non-metallic surface of PA pulleys ensures quieter operation.

Reduced Belt Slippage:

PA pulleys ensure a more secure grip on the belt, reducing the chances of slippage. This leads to more consistent motion and less noise associated with slipping or misalignment, which is a common problem in systems using traditional metal pulleys.

How PA Pulley Reduces Friction

Friction is an inevitable force in mechanical systems that can lead to wear, energy loss, and excessive heat buildup. PA pulleys are specifically designed to minimize friction and improve overall system efficiency. Here’s how they achieve this:

Low Coefficient of Friction:

Polyamide material has a low coefficient of friction, which means less resistance when the pulley and belt make contact. This results in smoother operation, reduced energy consumption, and lower heat generation. The low friction properties of PA pulleys help ensure that the system operates at optimal performance levels, with minimal energy waste.

Self-Lubricating Properties:

Polyamide pulleys are naturally self-lubricating, meaning they don’t require external lubrication for smooth operation. This is especially advantageous in systems that operate in environments where grease or oil is undesirable. The self-lubricating nature of PA pulleys reduces friction and prevents the need for constant maintenance, keeping the system running efficiently for longer periods.

Enhanced Durability and Wear Resistance:

PA pulleys exhibit superior wear resistance compared to metal or plastic alternatives. This is crucial in high-friction environments, as it helps extend the lifespan of both the pulley and the associated belt. Reduced wear means that the system can continue to operate smoothly without frequent replacements, further reducing friction-related issues.

Benefits of Using PA Pulleys in Mechanical Systems

Extended System Life:

By reducing friction and noise, PA pulleys help extend the lifespan of mechanical systems. Lower friction leads to less heat and wear, ensuring that the pulleys, belts, and other components experience less stress, thus lasting longer.

Improved Efficiency:

With reduced friction and noise, systems that incorporate PA pulleys tend to run more efficiently. The smooth operation leads to lower energy consumption, which is especially valuable in energy-intensive industries such as manufacturing, automotive, and HVAC systems.

Reduced Maintenance Costs:

PA pulleys require less maintenance due to their durable, self-lubricating nature. The reduction in friction and noise minimizes the need for frequent adjustments, lubrication, or part replacements, which results in lower overall maintenance costs.

Environmentally Friendly:

PA pulleys are more eco-friendly than metal pulleys because they don’t require constant lubrication, reducing the need for oil or grease. Additionally, their durability means fewer replacements, further minimizing the environmental impact of manufacturing and waste.

Applications of PA Pulleys

PA pulleys are used in a wide range of industries, from automotive to industrial machinery, due to their superior noise-reducing and friction-lowering properties. Some common applications include:

Automotive Industry: PA pulleys are used in engines and other systems where noise reduction and efficient power transfer are critical.

Industrial Machinery: In conveyor belts, compressors, and pumps, PA pulleys enhance performance by minimizing friction and noise, ensuring smooth operations.

HVAC Systems: PA pulleys help reduce noise in ventilation systems, providing quieter operation for residential and commercial environments.

Textile Machinery: The self-lubricating properties of PA pulleys make them ideal for use in textile machines where smooth operation and reduced maintenance are required.

PA pulleys are an excellent choice for improving the performance of mechanical systems by reducing both friction and noise. Their low coefficient of friction, self-lubricating properties, and vibration-damping abilities make them a valuable addition to a wide variety of applications. Whether in automotive, industrial, or HVAC systems, PA pulleys contribute to enhanced efficiency, reduced maintenance, and longer operational lifespans. For businesses looking to upgrade their systems with high-performance, noise-reducing, and friction-minimizing components, https://www.hunepulley.com/product/ offers top-quality PA pulleys that can meet your needs and ensure reliable, long-lasting performance.